E-Coat Ultrafiltration Shutdown & Restart Guide

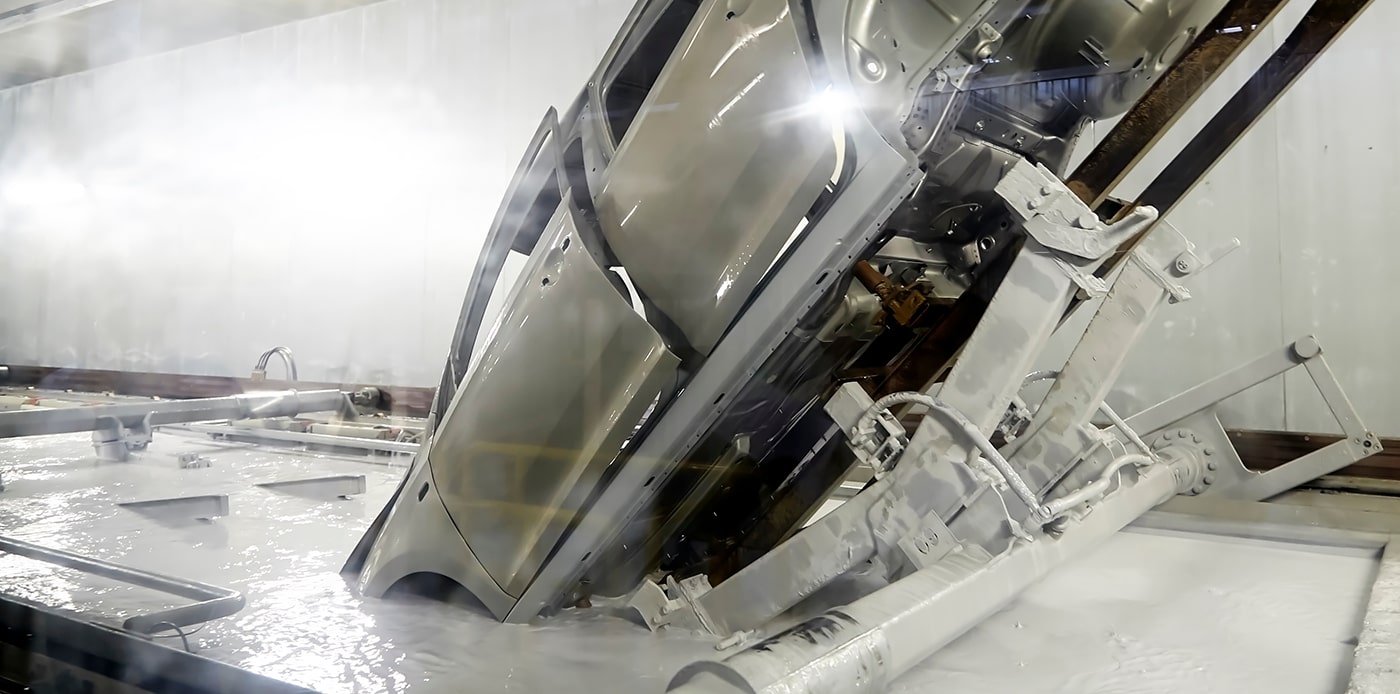

When it comes to electrocoating, the ultrafiltration (UF) system quietly does some of the most critical work in the entire process. It keeps the paint bath balanced, the rinses clean, and your coating quality consistent. As the end of the year approaches and production schedules slow, it’s the perfect time to give your UF system some extra attention.

Our E-Coat UF Shutdown & Restart Guide builds on what we’ve shared in past years with new recommendations to help you prevent issues, protect membrane health, and get back online smoothly when production resumes.

Why is your UF system critical during an E-Coat shutdown?

Your UF system runs nearly nonstop all year, filtering out contaminants and returning permeate to your rinses. A planned shutdown is your opportunity to clean, inspect, and reset that system before another production cycle. Taking the right steps now can:

- Extend membrane life and maintain consistent flux

- Prevent contamination or microbial growth during downtime

- Ensure stable startup conditions and quicker return to spec

What should you check before shutting down your UF system?

Before powering down, take time to capture key performance data and perform essential maintenance steps such as:

- Flux and pressure: Record normalized flux (at a consistent temperature) and differential pressure for each UF module.

- Permeate quality: Measure permeate and rinse conductivities, which will be your baseline on restart.

- Mechanical condition: Inspect bag filters, tanks, and lines for paint buildup or sediment.

- Inspect critical components: Inspect valves, pumps, and seals for wear, leaks, or vibration. Repair or replace components as needed to avoid mechanical issues at startup.

- Spare parts and consumables: Verify spare parts and consumables inventory. Confirm that you have adequate stock of membrane elements, seals, O-rings, filter bags, cleaning agents, and calibration standards.

- Spares and rotation: Identify modules showing lower performance for rotation or replacement, and confirm spare membranes and cleaners are on hand.

These steps give you a clear before-and-after snapshot and are invaluable for diagnosing issues later.

How should you safely shut down your UF system?

A proper shutdown prevents surges, contamination, and startup delays when production resumes. Think of it this way: A smooth shutdown sets up an easier restart.

When production wraps up, these are steps to shut down the UF system safely:

- Reduce flow and pressure gradually: This helps avoid surges.

- Flush the system: Use RO or DI water at least twice the system hold-up volume.

- Record key data: Permeate flux, differential pressure, and permeate conductivity are critical to establish baseline performance.

- Secure valve positions: Prevent backflow from paint or rinse tanks.

How do you store UF membranes during downtime?

UF membranes should always stay wet and protected in clean, temperature-controlled conditions to prevent fouling or damage. The right preservation approach depends on how long the system will sit idle.

For short breaks (<1 week):

- Keep membranes wet with clean RO or DI water.

- Maintain temperature between 5–40°C.

- Circulate every 2–3 days to prevent stagnation.

For extended downtime (>1 week):

- Use a membrane-approved preservative or pH-adjusted DI solution.

- Circulate weekly for 20 minutes and check pH stability.

- Protect against freezing and direct sunlight.

If you remove elements, flush and cap them wet with preservative, label them, and store indoors.

What’s the best way to clean and verify UF membranes?

The best approach is a staged clean-in-place (CIP) using approved chemicals and verifying flux recovery afterward. Use shutdowns to restore performance with a full cleaning sequence:

- Low-strength alkaline wash, which removes organic residues and paint carryover.

- RO or DI rinse

- Optional solvent-compatible rinse (if approved)

- Mild acid clean to remove scale.

- Final rinse to neutral pH

Perform a full CIP before shutdown. Running a CIP cycle helps remove residual paint solids and organic contaminants that can harden or cause irreversible fouling during idle periods. Use your membrane supplier’s recommended cleaning chemistry, following the gentle-to-aggressive sequence outlined above.

Evaluate whether any membrane elements require replacement. Compare current flux and pressure data to your historical baseline. If performance cannot be restored with cleaning, schedule element replacement before startup.

After cleaning, verify flux recovery and permeate quality before reintroducing paint. Aim for ≥90% of pre-shutdown flux.

How do you restart your UF system after shutdown?

Restart gradually with RO or DI water to confirm stable flux and pressure before introducing paint. When restarting, think of it as a mini commissioning event:

- Start with RO or DI water to confirm stable flux and pressure.

- Ramp up feed gradually while monitoring pressures and permeate conductivity.

- Watch trends closely during the first shift and compare to pre-shutdown baselines.

If performance is significantly lower than expected, a second rinse or mild cleaning may be required before loading paint.

Common UF Restart Issues (and Fixes)

| Symptom | Likely Cause | Recommended Action |

|---|---|---|

| Low permeate flow | Fouling or low temperature | CIP with approved cleaner; check temp |

| High differential pressure | Trapped air or scaling | Vent housings; perform cleaning |

| Rising permeate conductivity | Backflow or bypass leak | Check valves and flush lines |

| Odor or biofilm in storage | Insufficient circulation | Drain and refill with fresh water or preservative |

| Pressure surges | Trapped air or rapid startup | Vent and ramp gradually |

Final Checks and Continuous Improvement

- Document all readings and maintenance actions.

- Review what worked well and what could be improved for next year.

- Update your shutdown checklist based on lessons learned.

Even small adjustments like more frequent recirculation or tighter valve isolation can have a measurable impact on paint bath stability and UF performance.

Keep It Simple, Keep It Reliable

Planned shutdowns should be a key part of your uptime strategy. With consistent documentation, steady preservation, and careful restart procedures, your UF membranes will deliver reliable flux and consistent coating quality year after year.

If you’d like to discuss optimization strategies or health checks for your UF system, connect with our team. Learn more about our membrane solutions for E-Coat applications.

Frequently Asked Questions

A full shutdown following the above procedures is typically recommended during scheduled plant shutdowns or at least once per year. However, frequency should depend on production volume, bath loading, and UF system performance trends. Tracking flux and pressure over time helps identify when deeper maintenance is needed.

No. Cleaning chemistry should always match the membrane material and paint chemistry. Using non-approved cleaners can damage membranes or affect paint performance. Always confirm compatibility with your membrane supplier’s recommendations.

Regularly monitoring flux, pressure, and permeate quality, and performing timely CIPs, helps prevent irreversible fouling. Keeping membranes hydrated during downtime and documenting shutdown data can significantly extend service life and improve restart consistency.

Related Resources in the Knowledge Hub

Let’s Keep in Touch

Follow Solecta on LinkedIn and join our mailing list to keep up with our latest news.

Explore the Possibilities

Our team of application engineers and domain experts understands your industry’s unique challenges. (They’re also eager to solve them.)